Laminar Burn Process

The burning process in Wallas products is based on laminar combustion. Unlike turbine heaters that emit a very loud roaring or “jet engine” sound, our laminar combustion process is virtually silent, requiring no exhaust sound attenuation.

In addition to silent operation, our combustion process is also very clean. By maintaining perfect burner balance, meaning that the mix of oxygen, fuel, and temperature is correct, the process is very clean. A Wallas product will burn clean at all power settings, not requiring high power run periods to clean itself.

The 3 Essential Elements of a Laminar Flame

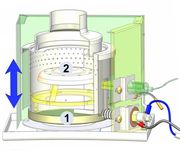

- The first required element is fuel. Fuel is pumped with a special solenoid valve pump. The pump is highly tolerant of voltage and current fluctuations, is very quiet and integrated into each Wallas product. A metered amount of fuel is pumped into the bottom of the burner (see No 1 in the picture).

- The second element is temperature. In the start phase, ignition temperature will be generated by a glow plug. When the flame ignites, it starts to heat up the radiator (see No 2 in the picture), and a short time later the glow plug turns off. The radiator reflects the heat to the bottom of the burner, and the resulting heat evaporates the liquid fuel into fuel vapor.

- The third element is retardation. There is a retardation zone in the burner, marked with a blue arrow. Retardation is needed to split the coal hydrogen chains. Diesel has more long aromatic chains than paraffin oil (kerosene) and thus needs longer retardation and higher temperature for breaking the chains entirely to achieve clean combustion.